Revolutionary Use of Ultrasound Facilitates 3D Printing Remotely, Even Within the Human Body

January 06, 2024

Concordia University's research team has introduced a groundbreaking technology known as "direct-sound printing," representing the first instance of constructing a solid structure using sound waves from behind an obstacle. While the path to commercial feasibility is still extensive, the scientists envision diverse applications for their remote-controlled 3D printing technology. The innovation holds potential for minimally invasive tissue engineering and bioimplant repairs within the human body, offering new avenues for medical interventions. Moreover, it could find utility in industrial repairs in challenging locations like the interior of an aircraft's fuselage.

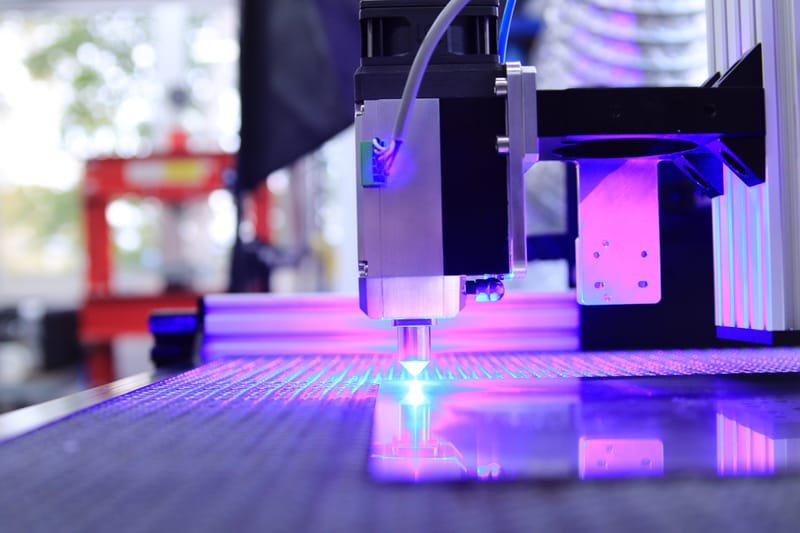

In contrast to conventional 3D printing methods that rely on extruding fluid materials through a nozzle and solidifying them layer by layer using light or heat, the team at Concordia explores a different approach. Traditional processes demand direct, focused contact between the energy source and the material for proper solidification. However, the Concordia team sought to overcome limitations related to accessibility to light or heat. Recognizing the unique properties of sound waves to rapidly focus and manipulate energy without direct contact, the team developed a novel solution to enable 3D printing in previously inaccessible environments, bridging a critical gap in the field.

CREDITS: SCIENTIFIC AMERICAN